Manufacturing industries need to be more efficient than ever before in today’s fast changing economic landscape. One of the main strategies for achieving this efficiency is excellent material and resource management. This is where MRP and ERP come in. MRP and ERP are two critical tools that will help to optimize manufacturing processes, increase efficiency, and ultimately drive corporate success.

What is MRP?

MRP stands for Material Requirements Planning. By identifying the raw materials and resources required to satisfy consumer demand, it is a method that aids manufacturing organizations in planning and managing their production process. Sales predictions, manufacturing plans, and inventory levels are all used in MRP to create a thorough material plan that guarantees prompt product delivery to clients.

The Benefits of MRP

MRP helps manufacturing organizations optimize their inventory levels, which is one of its primary benefits. Companies may prevent stock outs and excess inventory by using MRP to make sure they have the proper quantity of finished goods and raw materials on hand. By minimizing the amount of raw materials that go wasted, MRP helps businesses in reducing waste. Additionally, MRP gives users a clearer understanding of production schedules, which thereby enhances customer satisfaction and customer service.

The Drawbacks of MRP

- One of the major limitations of MRP is the amount of data entry and upkeep required.

- To maintain the accuracy of the MRP system, businesses must regularly update sales estimates, production plans, and inventory levels.

- MRP is also time-consuming to execute, making it inappropriate for small businesses with limited resources.

What is ERP?

ERP stands for Enterprise Resource Planning. It is a more complete system that integrates numerous company activities such as finance, human resources, customer relationship management, and supply chain management into a single system. Hence, ERP gives businesses a central database they can use to manage every facet of their business.

The Benefits of ERP

One of the most significant benefits of ERP is that it gives a comprehensive perspective of the business. By delivering real-time information on all business activities, ERP enables businesses to make better decisions. Furthermore, by streamlining procedures and removing redundant tasks, ERP can assist businesses in cutting costs. ERP also improves security for corporate data by consolidating it into a single system. .

The Drawbacks of ERP

- ERP may be expensive to establish and operate, which is one of its major downsides.

- ERP involves substantial modification to meet the particular demands of each firm, which can be pricey.

- Additionally, the lengthy implementation process may cause business disruption.

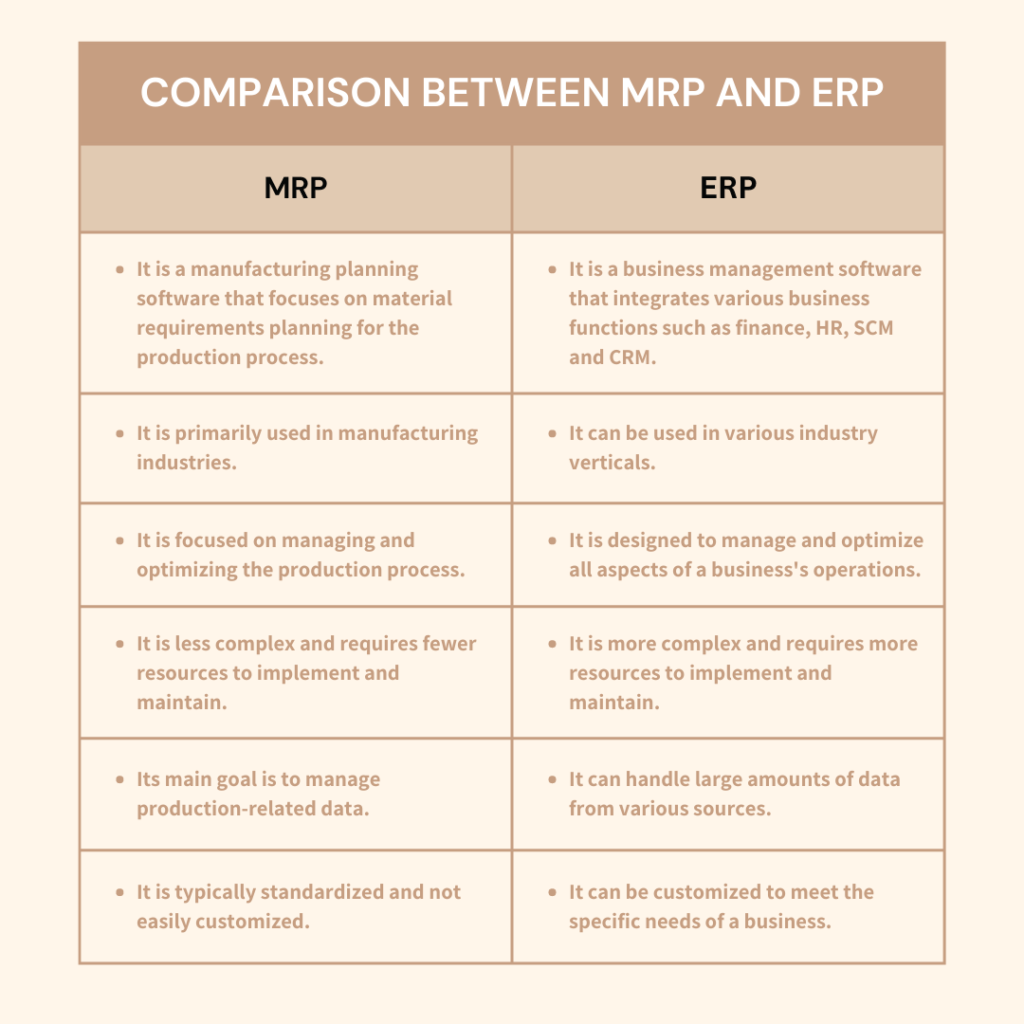

Difference between MRP and ERP

MRP and ERP vary primarily in that MRP is concerned with planning materials and resources, whereas ERP is concerned with the complete business process. MRP, a division of ERP, is frequently used by manufacturers to control their production process. Contrarily, ERP is a more complete system that businesses in different sectors may adopt.

MRP vs. ERP: Which one to choose?

Depending on the needs of the company and how complicated its business processes are, MRP or ERP is chosen. MRP may be appropriate for smaller manufacturing companies with less resources available to manage their production process. However, as ERP provides a more comprehensive solution, it can be the best choice for larger firms with more intricate business operations. The decision between them will ultimately depend on the unique needs of the firm.

Implementing MRP and ERP

MRP and ERP adoption need careful planning and execution. Finding the business processes that must be included into the system is the first stage. The next stage is to choose the proper software provider who can match the demands of the firm after the processes have been established. The business must modify the program after choosing the software provider to meet their specific requirements. The business must also teach its staff how to utilize the new system properly.

The Future of MRP and ERP

MRP and ERP have a bright future as industrial organizations explore ways to increase production and efficiency. Cloud computing and artificial intelligence, for example, are making it easier for businesses to build and use these technologies. Furthermore, their integration with other systems, such as customer relationship management and supply chain management, provides businesses with a more comprehensive perspective of their business operations.

MRP and ERP in the Digital Age

MRP and ERP have also seen substantial modifications as a result of the digital era in the industrial sector. More data is being made available to businesses to help them make better decisions thanks to digital transformation like the Internet of Things and Big Data Analytics. Additionally, employees are finding it simpler to access the MRP and ERP systems from any location at any time thanks to the use of mobile devices.

Advancements in MRP and ERP

Companies are continually getting better and more efficient ways to manage their business operations thanks to developments in MRP and ERP. One of the developments is the use of predictive analytics, which enables businesses to forecast future demand and modify their production schedules appropriately. Through the automation of repetitive processes, businesses are also able to save costs and increase efficiency.

Conclusion

In conclusion, MRP and ERP are two essential systems that can help manufacturing companies improve their productivity, reduce costs, and drive business growth. MRP focuses on materials and resources planning, while ERP encompasses the entire business process. Hence, the choice between them depends on the unique needs of each company. The implementation of these systems requires careful planning and execution, and advancements in technology are continuing to provide companies with more efficient and effective ways to manage their business processes.